Machine-building plant «PROFITEX», located on 4000 m2, is a modern design bureau, machining, electronic adjustment and assembly, service, marketing department. Over 70% of the staff with higher education are specialists with their own scientific and technical developments and achievements.

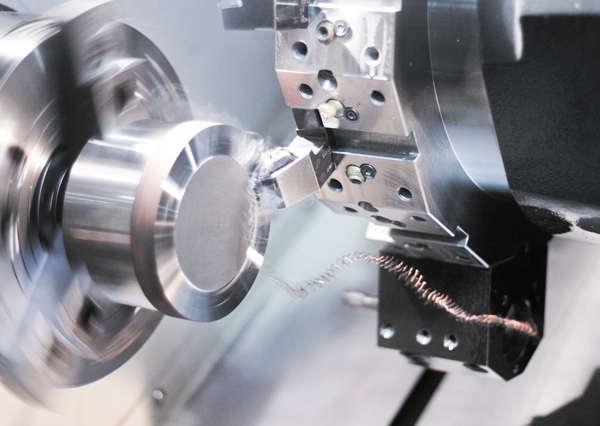

The company’s success lies in the fact that each order, starting from receipt, is tracked throughout the entire production cycle: development of design documentation, manufacturing of parts, procurement of components and assembly of equipment. The reliability of the equipment produced by us is laid, first of all, in the workshop of CNC machines. We can guarantee that parts are produced with great speed and accuracy. ADNK machines are equipped with Italian pneumatics and Japanese electrical equipment.

After the equipment has passed all stages of production, it is transferred to the service area, where it goes through the stages associated with running in and testing the equipment. During testing of a new machine, an electronic engineer programs the device for the technical requests of the owner of the machine.

LLC TD «PROFITEX» provides warranty, post-warranty and service maintenance of the supplied equipment. The service is carried out by highly qualified specialists, and on the territory of Russia there are 27 service centers equipped with everything necessary for the implementation of warranty service. Our service teams visit customers within two hours. We have a large fleet of our own. Cars are equipped with a mini warehouse with pneumatic and electrical equipment.

The company has a warehouse from which you can quickly pick up the most demanded items of packaging equipment.