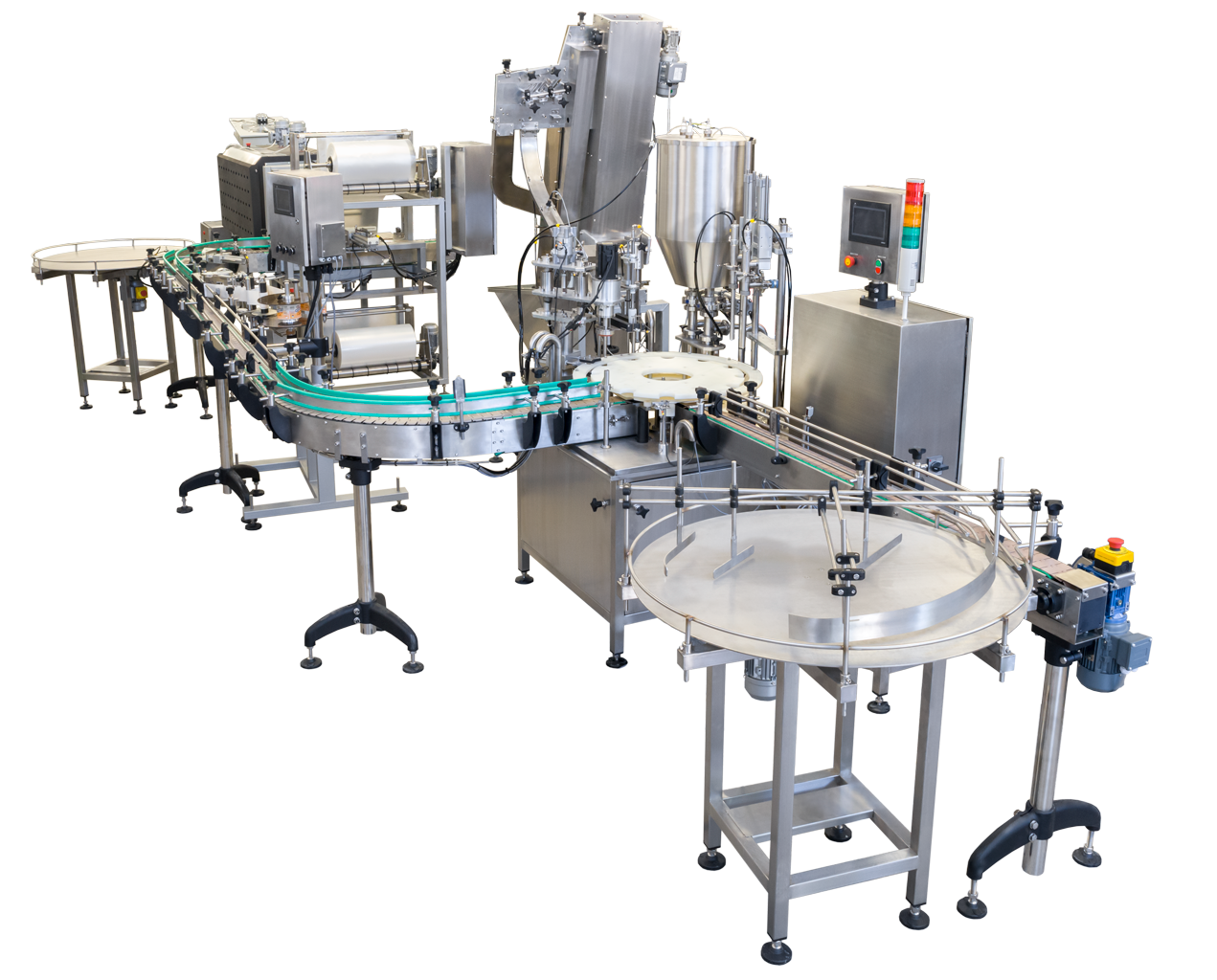

On the line, liquid — pasty products are bottled, in particular, the line packs syrup. Containers are fed to the line from a rotating storage table.

The complex is built on the basis of a carousel line, on which a step-by-step supply of containers is carried out by a carousel, product dosing with volumetric batchers, a feeder / orientator of the lid and screw caps.

After the line, there is a labeler for gluing a self-adhesive label with a temperature sensor, and a group packaging unit that allows you to form a group of cans, wrap them with foil and send them for heat shrinkage into a shrink tunnel.

The complex is built on the basis of a carousel line, on which a step-by-step supply of containers is carried out by a carousel, product dosing with volumetric batchers, a feeder / orientator of the lid and screw caps.

After the line, there is a labeler for gluing a self-adhesive label with a temperature sensor, and a group packaging unit that allows you to form a group of cans, wrap them with foil and send them for heat shrinkage into a shrink tunnel.

- Rotating storage table for bottle feeding

- Filling line «ADNK 39 LR» with automatic feeding and lid sealing

- Conveyor system for feeding and removing bottles

- Labeling machine for sticking a self-adhesive label on a bottle

- Rotating storage table for finished products

- Shrink wrapper with thermotonelle