The vacuum sealing line is designed for automatic thermo-sealing of plastic containers with food products. Laminated polymer films (with barrier properties) are used for sealing, the film is cut from a roll. The film can be either unprinted or printed. The gas injection option allows the container to be filled with an inert gas after evacuation. This allows you to increase the shelf life of the packaged product, the period during which the product does not deteriorate and does not lose its taste and usefulness is increased. This requires special containers with barrier properties to maintain the environment created in it for a long time. In a modified atmosphere, cottage cheese, cheese, meat and fish dishes with side dishes, semi-finished products, salads, snacks, baked goods, various bakery products, etc. are packed and stored. Ease of use, quality of packaging make this machine indispensable for use in large and medium-sized food industries.

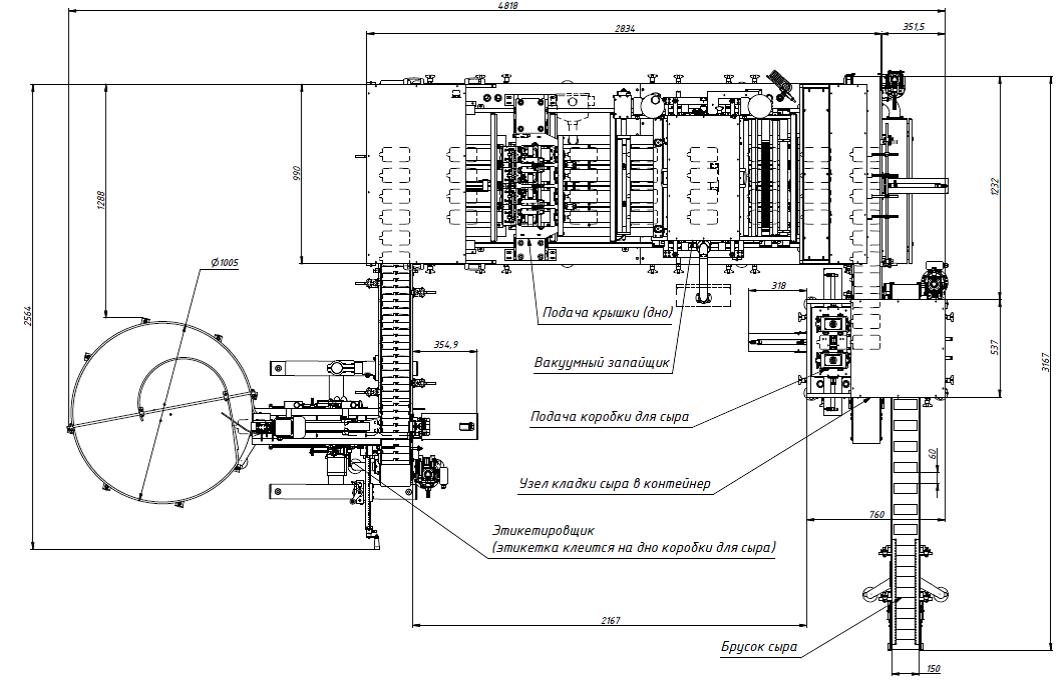

The equipment is manufactured individually for the customer’s product and container. In this version, the plastic packaging is a syrnitsa (lid with a backing) — the container moves initially upside down, the container is a lid for the consumer, the lid is sealed with a film, then the backing (bottom of the package) is sealed.

COMPOSITION OF EQUIPMENT (in accordance with TK):

- Unit for dispensing empty containers from a stack to a conveyor (magazine)

- Feeding conveyor for moving containers to the sealing line (2 m.)

- Manipulator with grips for placing a bar of cheese into a container (the cheese bars move along the feeding conveyor, the manipulator transfers the bars from the conveyor to containers that move along the feeding conveyor of the packaging line)

- Unit for pushing containers (with product) from the feeding conveyor to the sealing line

- Table (frame with a compressed air preparation unit) of a vacuum sealing complex with a container movement system (4 r

- Automatic film stretching unit

- Automatic film winding unit

- Container vacuum unit

- Vacuum pump

- The unit for sealing the film with notching occurs along the edge of the container (with or without a pull-off tab), at the moment of stretching the film, the film is notched out with subsequent sealing.

- Nozzles for supplying inert gas before sealing (without gas equipment)

- Node for feeding and capping the cover of the napkin (4 rows)

- Outfeed conveyor for removal of finished products (2 m.)

- A labeling machine for applying a self-adhesive sticker label on the lid (in fact, the bottom of the package, since the package moves initially upside down, i.e. the container is the lid, and the cover is the bottom of the package)

- Control unit (color touch screen with Russian language interface)

- Controller (Omron, Japan)

- Electromechanical drive

- Material — stainless steel (approved for use in contact with food)

- Productivity up to 1200 doses / hour

- Power consumption 5 kW

- Voltage 220 V, 50 Hz

- Pressure 0.6 MPa

- Compressed air consumption 800 l / min

- Weight 460 kg

- Number of rows 4 pcs

- Vacuum pump capacity 63 m³ / min

- Vacuum pump power 1.5 kW