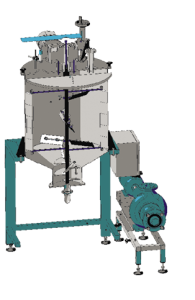

Standard filling containers of from 30 up to 200 liters are used for feeding the product into the measurer. Non-standard filling containers are used both for feeding the product into the measurer and for making the product. Non-standard containers are made on individual customer requests. The cheese container, for example, consists of two containers inserted one into another. The inner container of 100 liters stores the product. The surface between the two containers is filled with 80 liters of water — the water jacket. The water jacket is heated by an electrical heating element. Its power down-andup is controlled by the thermocontroller. It keeps the water jacket temperature within the predetermined range. The circulator provides for maintaining uniform temperature throughout the water jacket. Water is discharged through a tap on the drain pipe underneath the container. It is also possible to implement a container with a water jacket without a heating element, but with a hot water supply. The container is equipped with an electric drive blender inside. It is possible to set the required blending direction and speed. Cutting of the cheese curd in horizontal slices is carried out by a handoperated blender with slicers. Vertical slices are made by a cutter that is hand-operated for moving up and down within the container.