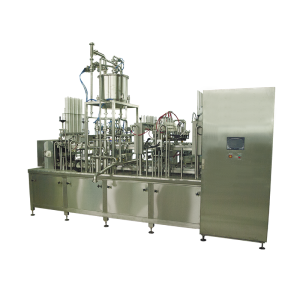

The machine is used for packing liquid and paste-like products into plastic cups from 100 up to 500 ml with diecut sealing made of Walkilid, foil, or rolled tape, and capping with a plastic lid.

- Working capacity up to 8000 cups p/h

- Voltage 380 V/50 Hz

- Power consumption, kW less than 1, 5

- Compressed air consumption l/min 1500

- Pressure, MPa 0,6

- Overall dimensions see the configuration

- Weight, kg less than 2500

- The number of rows 4

- Measuring method by volume

- Error range, % +/- 2

- Connection to the CIP-cleaner

- Automated cup feeding

- Automated lid feeding

- The Ultra Clean cleaning system

- The automated measurer control

- The accumulation table 1 200 mm (rotated)

- The air handling unit with a cleaning filter

- The feeding unit

- The cup monitoring sensor

- The automated measurer

- The die-cut feeding unit — from pile to cup (cassette)

- The die-cut monitoring sensor

- The die-cut sealing station

- The date marker

- The cap feeding and capping unit (from pile)

- The cup delivery unit

- The control center (a touch-sensitive monitor)

- The controller (Omron, Japan)

- The driver — servounit

- High productivity

- High die-cut sealing quality (a spiral pipe heating element)

- Vacuum balancer (against buckling)